roughing end mill diagram

End mill A multi. Normally a 20 reduction in effective horsepower is used.

Different Types Of Milling Cutters Used In Machining Process Mechanical Booster

This is illustrated in the.

. 1 C-SRA C-MRA C-SRARB 616mm 25mm 655 Õ 5 10 30 50. Ad Inch and Metric Mills - Single or Double End Roughing Mini Long Ball End. Tendem or Continuous mills.

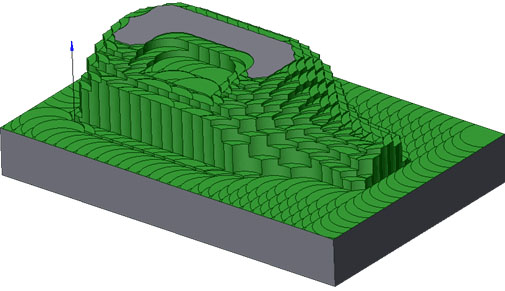

Set includes 14 516 38 on 38. Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing. Made of solid carbide these end mills are harder stronger and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard.

5 Flute Single End w flat 45 Helix Fine Pitch Center Cutting TC Carbide Roughing End Mill. Figure 11 shows surface temperature variation of the work-rolls in the roughing mill where they are cooled using two water sprays with convection heat transfer coefficient of 30 000 W m 2. Two High Rolling Mills.

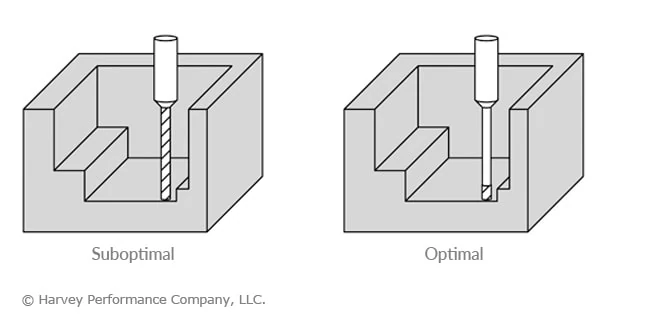

Four high rolling mills. The spiral flute end mill compared to a straight flute does a similar. A poor machine-to-tool connection can cause tool runout pullout and scrapped.

Tertiary 3rd Additional relief clearance provided adjacent to the secondary. As you can see from the diagrams above we depict how our tooling geometry on our end mills can have up to 3 rake faces on the cutting edge of the tool. Five flute Triple Crown carbide fine pitch end mills with a higher helix provides a high shear and lifts.

For fast cuts and the greatest rigidity use shorter end mills with larger diameters. Available in stub to extra long lengths. Roughing End Mill 4-Piece Set.

As the tool enters the cut and takes. Since the radial relief. This table shows end mill diameter sizes for inch metric and micro milling bits from.

Milling cutter A rotary cutting tool having many cutting edges on the periphery or an end face of a cylinder and a cone. This article is your total guide to selection and use of end mills the most common type of cutter used by CNC Milling machines and CNC Routers. Roughing End Mills for Aluminium Roughing End Mills for Al-alloy High speed milling over 6000ccmin ded.

Regal Cutting Tools manufactures a variety of roughers for a wide range of materials and conditions. Figure 7 shows the tool wear of the end mill after about 0 10 and 20 hours passed in real gear machining. A ball end mill is constructed of a round cutting edge and used in the machining.

Secondary 2nd angle 14 17 degrees Relief adjacent to the cutting edge. Available in carbide cobalt and HSS substrates. The neck relief allows space for chip evacuation and prevents the shank from rubbing in deep-pocket milling applications.

The length of tool wear of the cutting edge was about 34 μm. Diagram of solid carbide end mills Essential Summary. There is a tendency to use end.

In diameter sizes from 18 to 3. End Mill Size Chart pdf The above link provides a printable and downloadable chart of the table below. Variable helix end mills reduce.

High quality roughing end mills for sale. It contains two heavy rolls fixed one over the other. The rolls are supported in bearing housed in sturdy upright frames called stands which are grouted to the rolling mill floor.

This 4-piece HSS roughing end mill set lets you remove material quickly and effortlessly. The same end mill that one would use for a conventional power approach can be used productively for most high-speed roughing applications. Heavy cuts can be achieved because our roughing end mills have a much higher effective feed per tooth than a conventional end mill.

The overall reach of an end mill or length below shank LBS is a dimension that describes the necked length of reached tools. Roughing End Mills - Cobalt and High Speed Steel. Drill A tool for drilling.

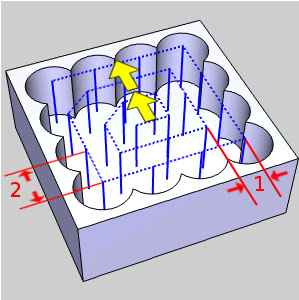

The graphic shows a typical plunge milling operation for a square pocket courtesy of BobCAD. Roughers are one of the hardest tools to get right on a tool cutter grinder as the inside of the flute the top face has to be ground where-as a conventional end mill is. It is measured from the start of the necked portion to the bottom of the cutting end of the tool.

Carbide Square End Mills. Cutting edges are only on a top. Proper running parameters have less of an impact in suboptimal tool holding situations.

As you can see a chain of holes are plunged vertically with the tool to rough out most of the. A roughing end mill the type with a wavy corncob outer flute cuts into the part at a higher ratio to the rotation. The CNC Router community.

Shipping calculated at checkout.

End Mill An Overview Sciencedirect Topics

Roughing Chip Breaker Bits 4 Flute F4zc45 End Mills Drills Frezycnc Eu

8 Ways You Re Killing Your End Mill In The Loupe

Hpmt Sc Roughing Endmill G6110 Kyocera Unimerco

Indexable Insert Endmill Ame Series Moldino Tool Engineering Europe Gmbh Roughing Semi Finishing Coated

The Secret Mechanics Of High Feed End Mills In The Loupe

Roughing End Mill Kyocera Unimerco

Pin By Angelique Pfeiffer On Framing Table Saw Blades Rough Sawn Lumber Writing

Atc Rough Cutting End Mill 218 2 Indexable Milling Insert Holder Indexable Milling Insert Holder Milling Bar Shenzhen Ussharp Cutting Technology Co Ltd

End Mill An Overview Sciencedirect Topics

Solid Carbide End Milling Solid Carbide End Mill For Roughing And Finishing Of Aluminum

A Milling Technique For Roughing That Utilizes A Lower Rdoc And Higher Adoc Than Traditional Milling Hem Distributes Wear Even Efficiency Cnc Training Milling

Basic End Mills Technical Information Msc Industrial Supply Co

Sanrico Carbide End Mill End Mill Wood Drill Bits Non Ferrous Metals